| | US Army & Navy 45ft Tug |  |

|

|

|

| Author | Message |

|---|

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: US Army & Navy 45ft Tug Subject: US Army & Navy 45ft Tug  Thu Oct 29, 2015 3:51 pm Thu Oct 29, 2015 3:51 pm | |

|  For my next project, I am going to build one of these - I hope. I purchased a fibreglass hull from the internet, which came with a plan. As you can see, the plan does not offer a lot of information, in particular the position of the deck. However, it fits many of my criteria, being reasonably short, and not requiring a hull to be built  So far I have made a stand and ordered a propshaft. I have started making a skeg to support the rudder. I have a couple of 380 size motors, and will use one of those. I also have spare servos after the need to test several for the ramp on Rhum.   Barrie | |

|

| |

Tug--Kenny

Lost But Never Forgotten R.I.P

Posts : 284

Join date : 2011-06-11

Age : 82

Location : Newport, South Wales,UK

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Oct 29, 2015 8:54 pm Thu Oct 29, 2015 8:54 pm | |

| That will turn out a nice tug Barrie. You have all the information you need. I would start by printing the drawings out to the exact size of the hull and a lot of measurements will fall into place. This is how I scratch build my stuff. To answer your first question, the deck would line up under the holes along the top edges of the hull.  keep us posted ken | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Fri Oct 30, 2015 7:26 am Fri Oct 30, 2015 7:26 am | |

| Kenny Thanks for the comments. In fact the drawing is the correct size - maybe the photo doesn't show that. Apparently the people who made the hull, American, also made a larger one as well. Its a pity they didn't mould in the rubbing strakes  I think fitting those will be my first job, along with the propshaft. Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Fri Oct 30, 2015 12:05 pm Fri Oct 30, 2015 12:05 pm | |

| Just saying to our new member Mark 9 aka Goon) that i love the american tugs, especially the old Railroad Tugs of the early 20 century. this tug hull of yours Barry reminds me of a squat Ryhope, once marketed by Caldercraft. The bow profile is very similar.

look forward to watching this one matey especially after that great last build of yours.

Enjoy the build.

neil. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Oct 31, 2015 2:29 pm Sat Oct 31, 2015 2:29 pm | |

| The propshaft arrived this morning, ahead of the material for the rubbing strakes, so that is what I fitted today  It was quite a tight fit to get it through the hull as its very slim at the back. I'm only using a slim M2 shaft. Its now in and fixed firmly - just need to fair in the filler round the exit of the shaft. I have also started making the rudder - I'm fabricating it from plastic card and some brass tube. I want it to pivot on a brass bolt which will allow me to remove the rudder to extract the propshaft if required. I spent quite a bit of time yesterday trying to source M1 brass bolts. Cornwall Model Boats list them but were out of tock, so I ordered 1.2mm, only to receive a call saying they were also out of stock  All the other suppliers I found were asking more for postage than the bolts.  I finally found some 10BA ones this morning at a sensible price, so have ordered those - hope they are OK. The last job was to make a cardboard template for the deck. Barrie   | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sun Nov 01, 2015 6:29 am Sun Nov 01, 2015 6:29 am | |

| Does anyone have any suggestions for the glue to use to stick the rubbing strakes onto the hull. They will be plastic and the hull is fibreglass.

Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sun Nov 01, 2015 1:47 pm Sun Nov 01, 2015 1:47 pm | |

| you can either use 2 part liquid epoxy or superglue, barrie.........if you use epoxy mark the centre line of the belting longitudinally onto the hull and drill with a small diameter bit every 20 mill around the hull.

scuff up the plastic and the hull with roughish grade paper and then glue....the holes drilled will act as an anchor for the epoxy to hold the plastic to. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Tue Nov 03, 2015 2:57 pm Tue Nov 03, 2015 2:57 pm | |

| Thanks Neil - I think it will be super glue - less chance of making a mess  My supplies arrived this morning so I was able to finish the rudder, apart from finally sticking the post in place. I want to wait until I have established the line of the deck to ensure clearance. I had marked the position of the rubbing strakes so was l set to attach them, until i reached for the super glue and found the bottle welded tight    Before stopping work and going to buy some more, I cut a number of strips of 2 mm plasticard to make the deck supports - double layer. At the garage I could only find tiny tubes of super glue - and they cost £2.99   - a quick online order is called for I think. Barrie  | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Tue Nov 03, 2015 10:22 pm Tue Nov 03, 2015 10:22 pm | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 04, 2015 1:42 pm Wed Nov 04, 2015 1:42 pm | |

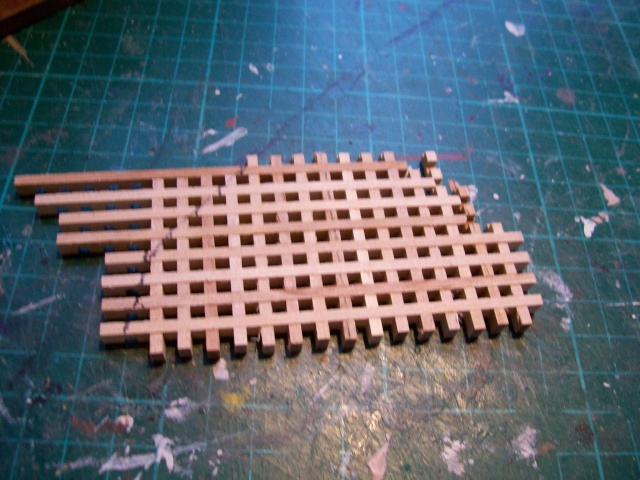

| Change of plan  The expensive tube of super glue I bought yesterday turned out to be gel, not thin as I thought  , so instead of fixing the rubbing strakes, I fitted the supports for the deck. The first layer fixed with epoxy, the second with polystyrene glue. I have also started making the grating for the rear deck. It has been brushed with aliphatic resin, and is ready for cutting to shape, and fitting into a frame. Barrie   | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 04, 2015 2:50 pm Wed Nov 04, 2015 2:50 pm | |

| Hi Barrie, this looks an interesting boat to build, it's coming along nicely.   I have a question, did you cut all the slots for the grating or can you buy lengths of it and what material is it please ? wood or ? | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 04, 2015 2:53 pm Wed Nov 04, 2015 2:53 pm | |

| Paul,

You can buy kits for various sized gratings. They are basically strips of slotted wood that you put together to make the pattern. A number of suppliers list them, although I think they all come from Poland!

Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 04, 2015 7:55 pm Wed Nov 04, 2015 7:55 pm | |

| thanks Barrie , I have now found them on ebay, not that I need any at the moment but handy to know  T | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Nov 05, 2015 1:21 pm Thu Nov 05, 2015 1:21 pm | |

| I have now fitted the support for the steering servo - a little tricky as there is not much room between the prop shaft and underside of the deck - good job it was one of the small servos  I also fitted a base to fix the motor to - a 380 size motor, and fitted one cross brace to support the deck before I had to turn to taxi duties  . My supplies of thin super glue and also my clevises arrived this morning, so I 'should' have everything now, at least until I come to the fittings. Barrie  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Fri Nov 06, 2015 6:30 pm Fri Nov 06, 2015 6:30 pm | |

| Today I made and installed the rudder linkage. This was quite tricky because of the lack of space, and it may need adjustment again when I come to fitting the grating at the rear. I also started fitting the rubbing strakes only to find that I didn't buy enough material  . I have the two full length ones fitted, but nothing left for the two shorter ones. I'll have to search my bits box and hope I can find some as there is no stockist anywhere near here. Next job is to work out where the battery and ESC are going to go. There is not a lot of space for a battery pack - I have a 6volt AA pack which I will have to use I think. Nothing else will fit, unless its a LiPO pack. Barrie   | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Fri Nov 06, 2015 10:26 pm Fri Nov 06, 2015 10:26 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 07, 2015 12:10 am Sat Nov 07, 2015 12:10 am | |

| |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

| |

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 07, 2015 8:51 am Sat Nov 07, 2015 8:51 am | |

| Paul, Yes and no  The bit that fixes the arm to the rudder is from a 13 amp plug, the arm is brass strip soldered on. These work well, although it is sometimes tricky to get the screw to grip tight enough as usually only one or two threads are through the body. I have in the past used the whole pin - depends on space etc. Battie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 07, 2015 8:56 am Sat Nov 07, 2015 8:56 am | |

| Thanks for the quick answer Barrie, I'll keep watching for more recycling ideas  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 07, 2015 1:19 pm Sat Nov 07, 2015 1:19 pm | |

| I decided I should try to work out where the electrics were going to fit. Its not a very big hull, and particularly is quite narrow. This is my attempt to see where it will go.   Its going to be difficult to get a neat insatllation  I then proceeded to make a container for the LiPo battery, I ditched the idea of the AA pack, fixed some card to take the ESC and Rx.  Finally, I cut and trimmed the deck after fixing two more cross braces, and strengthening the opening. The deck is not yet fixed as I realised that I would have no access to the servo once it was stuck down. I am not sure if I can move it, but at least I will need to ensure the linkage doesn't need any changes before fixing the deck.  Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sun Nov 08, 2015 1:25 am Sun Nov 08, 2015 1:25 am | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

| |

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Mon Nov 09, 2015 3:24 am Mon Nov 09, 2015 3:24 am | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 11, 2015 2:11 pm Wed Nov 11, 2015 2:11 pm | |

| Having failed to find a local supply of the half round rod, I had to order from Cornwall Model Boats, and it arrived this morning, along with fittings I will require later. It is now in place, and the hull is a step nearer being ready for painting.  After fitting the strip, I set about making and fitting the bulwark supports. These are made from 1.5 mm brass rod and are superglued to the deck and bulwark.  Finally before I had to clean up the workshop before Grandson arrives - he complains if the bench isn't clear - I cut and fitted the bulwark capping strips. These are cut from 0.5 mm plasticard, and glued with superglue. Once the glue is fully hard, they will need trimming.   Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 11, 2015 6:34 pm Wed Nov 11, 2015 6:34 pm | |

| |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Nov 12, 2015 8:03 am Thu Nov 12, 2015 8:03 am | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Nov 12, 2015 5:48 pm Thu Nov 12, 2015 5:48 pm | |

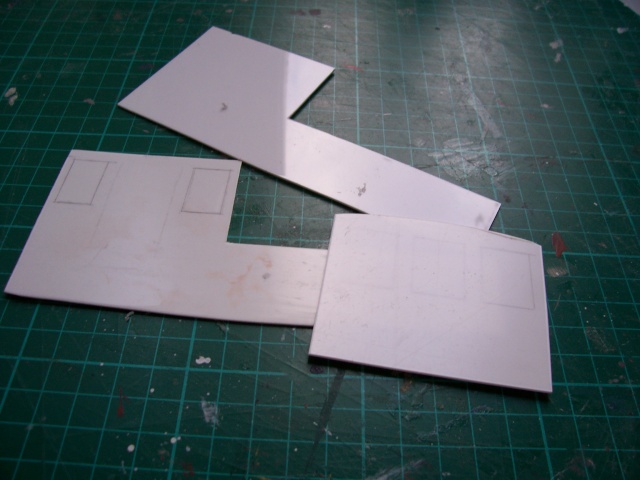

| The bulwark capping rail has been trimmed, some minor dings filled and sanded. I though I was ready to paint the hull, then remembered that I haven't opened any freeing ports or hawse holes  , so that's the next job. I am anxious to get at least a primer spray on to the hull while the mild weather lasts.  While waiting for the filler to dry, I started cutting the parts for the superstructure. These are cut from 1 mm plasticard. Unfortunately the piece I have is very hard and a bit brittle, so getting clean window openings will be a challenge  Barrie  | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 14, 2015 9:30 am Sat Nov 14, 2015 9:30 am | |

| this is one sweet build........she has a lovely hull shape and is going to be a lovely little model. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 14, 2015 2:19 pm Sat Nov 14, 2015 2:19 pm | |

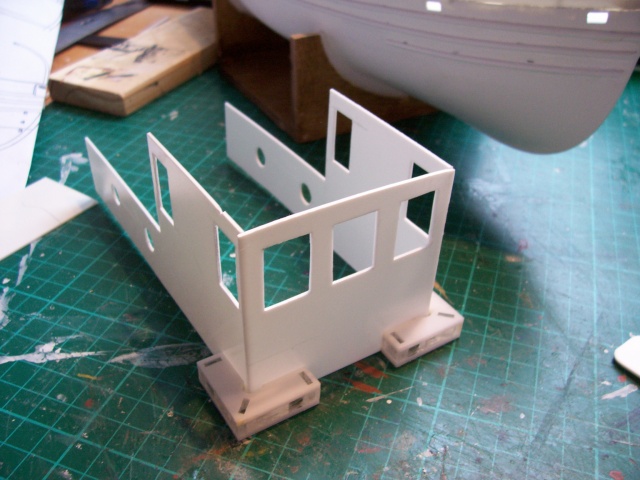

| Thanks for the kind comments.  I have made the final preparations for spraying the hull - fitted the attachment points used for lifting the tugs from the water, and masked a couple of areas for fittings to be added later. Now all I need is the mild weather to continue  .  I have started assembling the superstructure, after having to remake some parts as the not all the drawing is to the same scale apparently    Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 14, 2015 5:06 pm Sat Nov 14, 2015 5:06 pm | |

| I like those little corner squares Barrie for holding the sides together..........what are they , neil. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 14, 2015 6:16 pm Sat Nov 14, 2015 6:16 pm | |

| Neil,

They came from here - not cheap and these are more expensive than when I bought mine. I believe there are others in the market place, but these were the ones I found first.

Barrie

http://www.yorkmodelmaking.co.uk/useful-bits | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sun Nov 15, 2015 3:35 pm Sun Nov 15, 2015 3:35 pm | |

| Very windy at the lake this morning so I came home and sprayed the hull with primer. I thought I had a can of red, but it turned out to be white, so no photo as it doesn't look any different.    I will now have to hand paint, which is no bad thing as it makes it easier to touch up if needed, and the hull is quite small. Barrie | |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Mon Nov 16, 2015 9:24 am Mon Nov 16, 2015 9:24 am | |

| - barriew wrote:

- Neil,

They came from here - not cheap and these are more expensive than when I bought mine. I believe there are others in the market place, but these were the ones I found first.

Barrie

http://www.yorkmodelmaking.co.uk/useful-bits Whilst nosing around the internet I found these and they seem a little cheaper, 4 clamps £28 am I reading it correctly ? http://www.ngtrains.com/Pages/Glues/gluestools.html#Tools | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Mon Nov 16, 2015 12:53 pm Mon Nov 16, 2015 12:53 pm | |

| Yes - they are the same idea. As I said the ones I bought were the first UK sourced ones I found when looking a few rears ago. Model Railways are where these tools were developed for constructing buildings.

Some other interesting items on that site - I will have to re-visit when I have time.

Barrie | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Mon Nov 16, 2015 3:20 pm Mon Nov 16, 2015 3:20 pm | |

| More work on the superstructure today. Trying to build it off the model was not a good idea, and I had to remake some parts.   There is another bit that goes in front of the wheelhouse, and I cant decide whether to make it part of the wheelhouse, or fix it permanently.  Barrie  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 18, 2015 1:07 pm Wed Nov 18, 2015 1:07 pm | |

| Roof and raised deck now fitted, ready for trimming, and doors added.  I was lucky enough to find a piece of wood which has almost the exact profile for the funnel, so that solves one construction problem    It does however leave me one challenge - at the rear of the funnel there is a ventilation grating which at the moment I am not sure how I can make.   Finally for the day I applied some paint to the hull - I don't think this is the correct colour however  - which Humbrol colour do you use for the underwater area? This is Red Brown. Barrie  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Nov 19, 2015 3:00 pm Thu Nov 19, 2015 3:00 pm | |

| After another coat, I think I will accept this colour. After some varnish, I think it will be OK.  I have trimmed the roof and deck of the superstructure, and started building the forward extension. I decided it would be best attached to the main part.   Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Fri Nov 20, 2015 3:07 am Fri Nov 20, 2015 3:07 am | |

| |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 21, 2015 3:47 pm Sat Nov 21, 2015 3:47 pm | |

| More work on the superstructure - I'm trying to get it ready for spraying in case we get another mild day soon  . I've also closed the gap at the stern. My grating was too clumsy, and looking at some photos, they just appeared to have flat decks, so I have put in a piece of card. Its a tight fit, and I will add a fitting of some sort to allow me to remove it if I need access to the rudder.   I have also given the topsides of the hull a first coat of black.  Barrie | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Mon Nov 23, 2015 12:59 pm Mon Nov 23, 2015 12:59 pm | |

| The second coat of black was applied this morning and the masking tapes removed. When its hard I will use Humbrol Mattcote to cover the whole. I have added some rails to the superstructure and managed to get a coat of primer and gloss on by using the fact that the clothes dryer was on in the garage thus lifting the temperature    I have started making the main towing bollards for the deck. The attached picture is not very good - I'll try to take a better one tomorrow! Barrie  | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Tue Nov 24, 2015 1:04 pm Tue Nov 24, 2015 1:04 pm | |

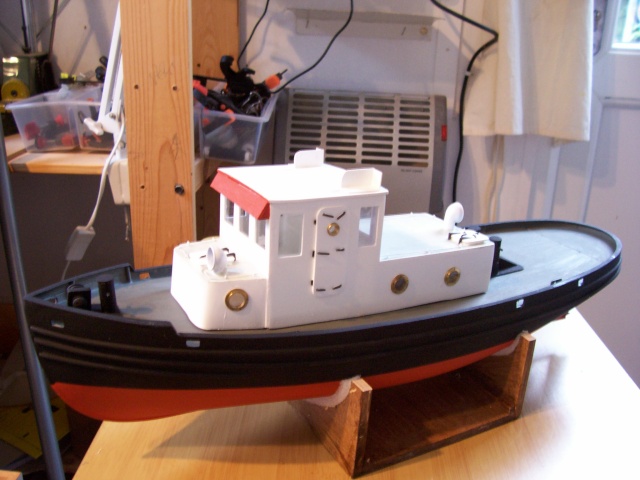

| Here is a better picture of the current state. The superstructure has had a coat of Halfords Appliance White, and is ready for the details to be added.  I have also built the towing bollards and these are ready for painting.  Decks to paint now and some other fittings to attach. Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Wed Nov 25, 2015 8:28 pm Wed Nov 25, 2015 8:28 pm | |

| man, that is superb................looks a real cracker. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Nov 26, 2015 7:39 pm Thu Nov 26, 2015 7:39 pm | |

| A little more progress over the last couple of days or so. The deck has now been painted (2 coats) and also the other flat surfaces have had one coat as has the'visor'. The main towing bollards have been painted and fixed in place, and the front bollard and winch has been made ready for painting. Next jobs are the mast, which I am making from plastic tube as I don't have the correct sizes of brass  , and fitting the portholes and glazing the windows. I also need to make a lot of hinges and locking handles etc for the doors and hatches. Only one photo today as my camera has decided to take more out of focus shots than in focus ones    Barrie  | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Thu Nov 26, 2015 7:55 pm Thu Nov 26, 2015 7:55 pm | |

| there's nowt wrong with making masts from plastic Barrie..they tend to give when you catch them instead of bending like brass can.

I also used to use the top section of hollow tube fishing rods when I built trawlers..you could run the light wiring up them and they never broke when clobbered.

I must saythis is a lovely build, and the more I see it taking place, the more I wonder at my age and back problems why the hell I don't build small boats instead of the five footers I persist in building...would be much more sensible.....

but as my good old mum used to say god bless her....."when are you going to start being sensible ya daft bu**er."

neil. |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Fri Nov 27, 2015 9:27 am Fri Nov 27, 2015 9:27 am | |

| Neil, i gave up on 'big' models because I don't have room to store them, plus its getting more difficult to carry and launch them. The downsides to sticking to approx 50 cm max. models is twofold. One they don't take as long to build, and so storage is still an issue as I just build more  . Two there is a more limited choice of subjects. Barrie | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 28, 2015 6:04 pm Sat Nov 28, 2015 6:04 pm | |

| More detail added today - handles and hinges on doors and hatches. Not as detailed as Gribeauvals  Portholes installed and windows glazed. Mast and funnel are next I think, then a few pipes and fillers. I seem to be short of lamps for Nav lights etc, and a searchlight. I think I can make the latter.   Barrie | |

|

| |

Guest

Guest

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sat Nov 28, 2015 11:27 pm Sat Nov 28, 2015 11:27 pm | |

| |

|

| |

troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sun Nov 29, 2015 8:25 am Sun Nov 29, 2015 8:25 am | |

| Coming along nicely Barrie,  What did you make the catches and hinges from or can you buy them ? | |

|

| |

barriew

Captain (moderator)

Posts : 2631

Join date : 2011-11-26

Age : 83

Location : Thaxted, Essex

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  Sun Nov 29, 2015 9:41 am Sun Nov 29, 2015 9:41 am | |

| Hinges on the hatches cut from black plasticard (sort of L shape) and catches and door hinges are some black piano wire I had.

You can buy various white metal hinges but it depends on the size you need.

Barrie | |

|

| |

Sponsored content

|  Subject: Re: US Army & Navy 45ft Tug Subject: Re: US Army & Navy 45ft Tug  | |

| |

|

| |

| | US Army & Navy 45ft Tug |  |

|