| | | STEAM HYDRAULIC LIFEBOAT |  |

| | |

| Author | Message |

|---|

Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Oct 14, 2017 10:49 pm Sat Oct 14, 2017 10:49 pm | |

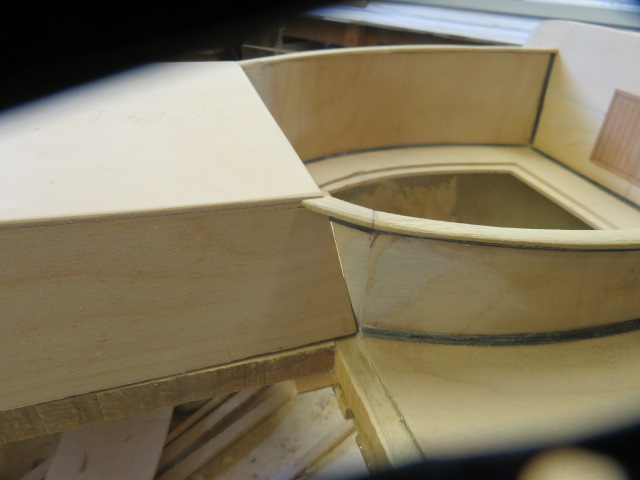

| what a Whoopsie Daisies up.........I had pressed a button yesterday on my keyboard.........hadn't a clue what I did, and it just froze everything.........couldn't even log out, so had to call my brother in to have a look................last night......seconds later I was up and running again... anyway I have fitted both end boxes permanently and filled all gaps with filler. in fact apart from a dose of 15minute setting epoxy to fixe the top leading edge of the stern box to the bulkhead, all other edges of both boxes were located and fixed with a generous dollop of polyester filler.............it has no strength as a gluing compound unless it is left to set around and in between both joints and then it can be very effective. once this has set firmly, tomorrow will be used to fit the deck in sections and then hopefully on Monday I can give the whole boat a good sanding and clean up ready for showing a "work in progress" at the Blackpool show next weekend.    |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Oct 15, 2017 5:03 pm Sun Oct 15, 2017 5:03 pm | |

| looking better with all its deck on,,,,,,,,,,,but the side pieces have not been fitted yet as I am working on the nozzle outlets which I'll post later. and whilst glue was setting I had chance to give the aft port quarter of the end box a good sanding......looks a little better cleaned up.......but more to follow.     |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Oct 16, 2017 4:21 pm Mon Oct 16, 2017 4:21 pm | |

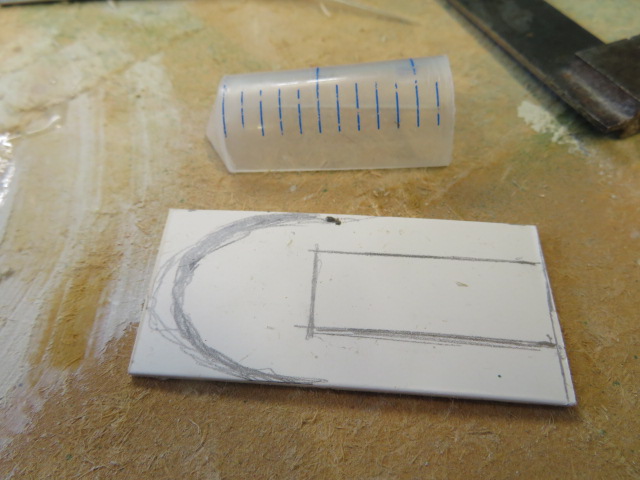

| how to turn a syringe into a water jet nozzle.. first choose a syringe the same diameter as the nozzle, and cut in two. take each half and place on a sanding linisher and sand a tapered flat onto the "base". cut a base so that you have an overlapping flange for attaching to hull side. glue the syringe to the plasticard base using plumbers pipe glue. take some milliput , and mix the two parts together.

apply to the syringe/flange and mould into a reasonable shape as per plans, both outside the tube and inside giving some thickness to the "wall" as it is going to be moulded and castings taken from it.use water to get a smoother finish, although it will need sanding afterwards.

leave overnight to set, preferably on a warm radiator. it will go rock hard.

|

|   | | Guest

Guest

| |   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Oct 16, 2017 4:28 pm Mon Oct 16, 2017 4:28 pm | |

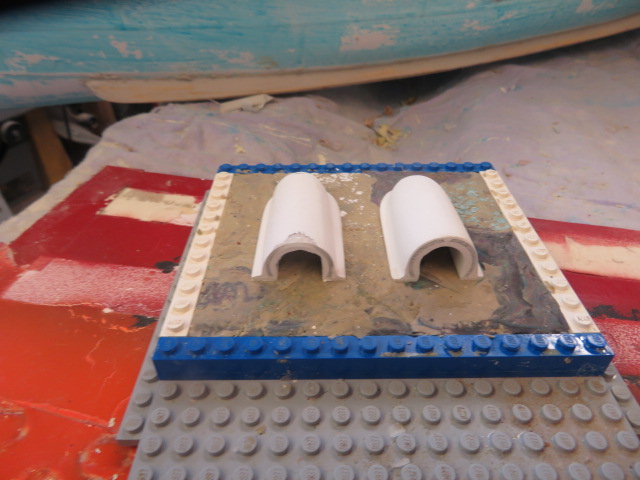

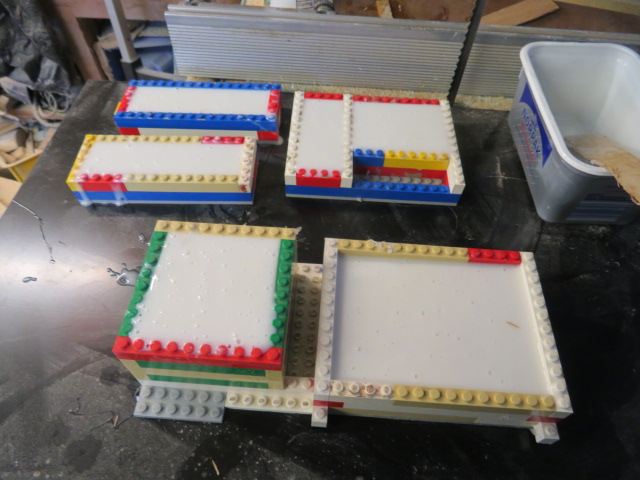

| and the final stage of this transposition from syringe to nozzle is to cast it. Using old faithful Lego to make a casting box, I built one up to surround the two nozzles and layered the base with moulding plastecine , placed the fittings on the compound. I filled the open ends of the nozzles with a dollop of plastecine to aid splitting the mould later, and then mixed my RTV [room temperature vulcanising rubber with catalyst and a drop of water [to aid humidity rather than finding someone's vacant airing cupboard. A tip I was given by the technical department of Alex Tiranti some years ago]..........and pour into the mould case to cover. Leave to set and cure.    |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Mon Oct 16, 2017 8:04 pm Mon Oct 16, 2017 8:04 pm | |

| I think there is some fear and trepidation from modellers regarding moulding their own fittings, and after I have posted similar threads I get a pm or an email asking whether it is as easy as I make it out to be............the only problem that anyone will have is wastage of resin, as the polyurethane resin that I use these days needs to be spot on weight wise AND so I use a small digital scale to get the weight exact per part, and the shelf life of the resin...........it can be dear, and I use CFS for my supplies and I make sure that I have all my fittings ready and ready moulded in rubber before I buy a two pack of resin, and then little is wasted before it goes off. the actual making and cutting of the moulds is very easy so long as decent masters are made.........they don't have to be perfect, as they can be cleaned up once out as a moulding, ...... I do also have a centrifugal casting machine and melting pot for casting in white metal and in such circumstances just use a harder grade RTV rubber to take the heat of the metal. so on to the mould today. the first half cured and so time for the second half. over the years I used a release agent supplied by Tiranti's of Reading where I would buy my rubber, and it was in aerosol spray cans, but then all of a sudden they could not supply because they said their couriers and Royal Mail would not carry spray cans...........I spoke to the tech dept, and the guy said why was I wasting my money on spray cans anyway, as common good old Vaseline was a far better release agent than any they could supply when moulding the two halves together. And once you have pulled the masters from the mould halves, you never need to re apply a release agent again anyway........it is only used to stop the second half of the rubber mould sticking to the first half when making the original moulds. so here it is, the finished mould for the two nozzles.     |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Oct 27, 2017 5:09 pm Fri Oct 27, 2017 5:09 pm | |

| I can't do anymore to the hull now until I have been to the centrifugal pump man over near Blackburn, and have been busy all week tending to my daughter who has been suffering from acute tonsillitis, and has not been well at all. kept me busy, poor thing........so hopefully will make contact next week. So, until then I have found a little time off this afternoon and cut myself some 4mm square strips of mahogany. These are the supports for the bench seats inside the Well deck at the stern. I set up a gauge on the band saw and cut 40 lengths of strip in two different lengths for the cross and vertical struts. I then used a jig that I had made to cut such struts for my Liverpool class boat nearly ten years ago so that I can cut half housing joints perfectly every time......only 80 joints to cut........160 cuts in total..........might be loosing the will to live at the end of it, lol. These eventually will be glued together using aliphatic resin and then sanded smooth..........A bit of repetitive woodwork never hurt anyone, lol       |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sat Nov 04, 2017 3:12 pm Sat Nov 04, 2017 3:12 pm | |

| All bench supports have now been cut, glued together and sanded down into sets of 3...........bit of a blunder in that I only cut enough for 60% of the supports that I had envisaged, but as there are no actual plans contemporary to the actual boats, only supposition and basic line and GA plans[ the nearest I had were blue prints that were lost 25 years ago]then modellers licence has to be used, and instead of 5 sets of supports per bench I am going to suffice with 3 sets. Unfortunately because of the lack of detailed plans,I make a bold statement here and say............all those models built of these steam lifeboats will always be with some modellers licence and none will ever be true scale, even that of the impressive Duke of Northumberland built by Les Jones. This is by no means a criticism, of his or anyone else's build.............just that true detailed plans are just not available, unless tucked away and hidden in some vaults somewhere for obscure reasons. I also soaked the laths for the bench tops the putting them across some deck beams with weights on to allow to dry, ready for cutting and fitting.   have also made the " access doors" into the rear end box, by laminating two pieces of ply together..........the inner piece being an exact fit to the rectangular hole which allows access to the steering servo........and the outer piece being larger in all four ways to overlap the hole, and drawn onto it the panelling and simulated doors for access.   small detailing, but presuming that the rest of the superstructure and wind shields to the aft well deck are made from the same material as the hull, either steel or iron, they will have had to have been riveted together. and so I have covered all jointing points with plasticard angle "iron" to simulate the same on the real prototype. "rivets" will be added later using glue sticks.   the capping rail to the well deck has now been added in 3 sections using 2.5mm obeche.......just needs sanding once the 5minute epoxy has cured   the gussets to the main engine casing from the well deck walls have been made and faired in, filled and sanded,..........and then the inner bench seats made.     benches made, temporarily fitted and Samson posts cut ready for shaping. I have brackets for these that I made for my pulling/sailing lifeboats....    crew getting stir crazy................need a shout soon....    |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Nov 05, 2017 7:29 am Sun Nov 05, 2017 7:29 am | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Sun Nov 05, 2017 4:47 pm Sun Nov 05, 2017 4:47 pm | |

| its getting better, Damien.........will have to sort out the pumps in the next week or so, and get them fitted and plumbed it. before I go much further though. |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Nov 07, 2017 8:06 pm Tue Nov 07, 2017 8:06 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Nov 08, 2017 9:16 pm Wed Nov 08, 2017 9:16 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Nov 09, 2017 5:34 pm Thu Nov 09, 2017 5:34 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 10, 2017 3:25 pm Fri Nov 10, 2017 3:25 pm | |

| A useful tip for those with a laithe. I have come to the point where I need to make the bases for the funnels......I have the brass should I need it to turn a base which will end as a plug to sit the funnels in for the Duke of Northumberland which is 25mm diameter, but the funnel for the Queen is over 30mm diameter and I haven't any brass of over 35-38mm to turn one for this funnel, and I know a man who needs one to fit that diameter funnel. so rather than buy a chunk of brass long enough to steady in a 3 jaw chuck on my laithe I decided to go down the route that I have done before. As you can see I throw little away in my workshop, thinking "one day"......and the used silicon gun tubes once empty is no different.Today was just one of "those days"... I cut the tube down to a length needed, and san one end into a wodge of plastecine, set on some greased baking paper.Then placing the tube into a margarine tub to prevent any leaking onto the bench I mixed some polyester resin.....same as what I use for laying up moulds and poured it into the tube, and left to set. Later I'll be able to turn the bases that I need from the solid cylinder of resin.     |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 10, 2017 7:11 pm Fri Nov 10, 2017 7:11 pm | |

| well, that went well.............I think not............a case of far too much catalyst to resin......which has resulted in the whole thing crazing and cracking. back to the drawing board, and start again.   |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 10, 2017 10:52 pm Fri Nov 10, 2017 10:52 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Nov 15, 2017 4:53 pm Wed Nov 15, 2017 4:53 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed Nov 15, 2017 5:01 pm Wed Nov 15, 2017 5:01 pm | |

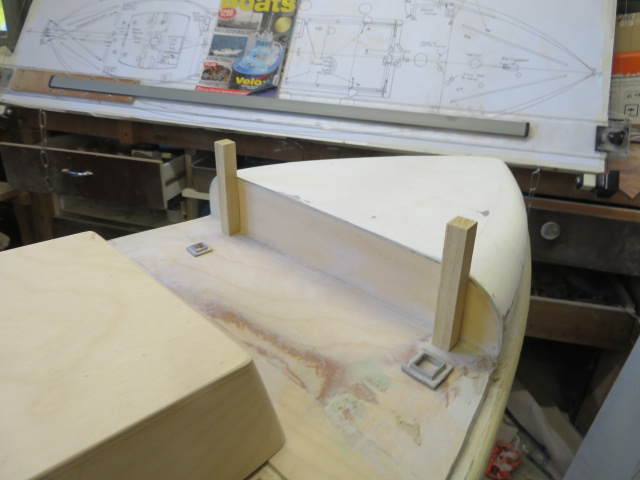

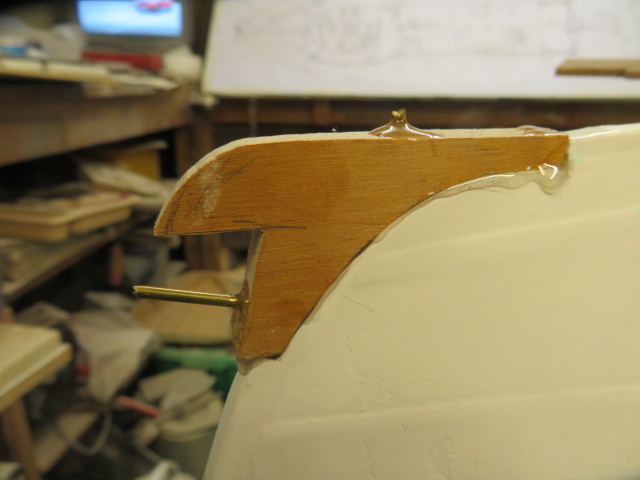

| made some moulds from rubber last night and poured the rubber in today........they are odds and sods such as small rope brackets, the supports for the navigation light boards, scuttle ports, well deck drainers and the funnel bases just waiting for those to cure. But then staring at the drawings, I realised that if I didn't make a rudder pintel foot, I'd have no rudder, and one embarrassment of my voith powered ferry going round in circles without steerage was enough for anyone, so made a "foot" from 10mm 5 ply, cut an indentation out of the grp keelson and stern post. Drilled the wooden foot, offered it up to the hull and drilled the hull, and then glued and pinned the foot to the hull with 15minute epoxy, and left to set. I can make the rudder now from laminated layers of 1.6mm ply running at right angles to each other layer, so that it won't warp and twist. more to come tomorrow.        |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Nov 16, 2017 12:10 am Thu Nov 16, 2017 12:10 am | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Nov 16, 2017 12:32 pm Thu Nov 16, 2017 12:32 pm | |

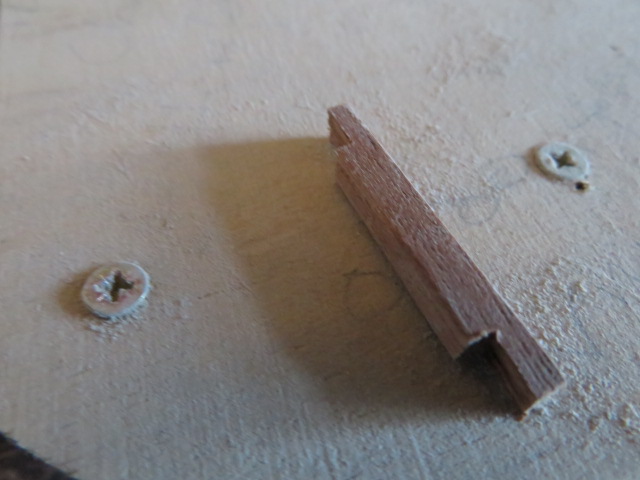

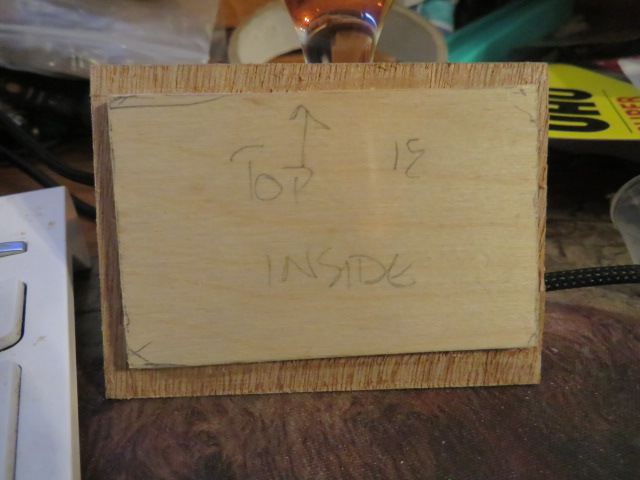

| Following on from the rudder skeg, has to follow the rudder itself..........and what a whopper it is. No doubt made large to give better steerage as I don't suppose there was much engine steerage from the water jets themselves. because it is so large, I decided to make it from birch faced ply for the inner section and mahogany faced water proof ply for the exterior. I also made it from four layers, the outside layers having the grain running vertically and made from 1.8mm ply. one inner layer of 2.0mm thickness had the grain running horizontal, and the final inner layer of 1.5mm ply with the grain running at 45degrees. I did this in order for stability of the timber, because running the grains alternately, the rudder, as big as it is will not then have a tendency to twist or warp, even if it spends a great deal of time getting wet.........which I doubt will happen anyway. Sadly with my bad back and arthritis they seldom get their bums wet anymore. you might notice from the first photo that on the rear edge of the rudder, the outer skin overlaps by around 10mm along its length. the other outer skin does also. this is to facilitate the square section brass tube that will be inserted into the trough, which then will be filed at sections to take the brackets that the solid brass bar that will run up through the square section, and through the holed in the brackets which will then be glued into the stern post..............making the whole rudder as one assembly..............if it confuses you, then it has certainly been a brain teaser to me, but all will be revealed once the rudder is glued together. I used aliphatic waterproof glue and plenty of clamps to give even pressure all over whilst gluing up. I'll release it in a few hours once cured.   |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Thu Nov 16, 2017 5:11 pm Thu Nov 16, 2017 5:11 pm | |

| I've just been looking at cut off valves for water pipes..............has anyone come across these two manifolds for hose pipes and if so how stiff are those taps. the reason of asking is whether a servo would be able to shift the tap..............this would be a dream come true if they could. If so I could do the system with just one pump. saw them on Amazon. neil   |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 17, 2017 12:09 pm Fri Nov 17, 2017 12:09 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 17, 2017 12:28 pm Fri Nov 17, 2017 12:28 pm | |

| |

|   | | troutrunner

Master

Posts : 573

Join date : 2014-01-23

Location : Lincolnshire UK

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 17, 2017 10:47 pm Fri Nov 17, 2017 10:47 pm | |

| I have a plastic "Y" piece tap two way connector with individual taps similar type of thing to your four way fitting and I have found that to open from closed position takes a reasonable effort, I don't think the small servo's that I have would have enough grunt to overcome the initial stiffness and get it moving.

I hope this makes sense and helps you Neil. | |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Fri Nov 17, 2017 10:54 pm Fri Nov 17, 2017 10:54 pm | |

| thanks paul.........Dave Milbourn and a chap off the US site that i'm a member on both have suggested a route may be solenoid switches fitted to manifolds, with the manifold taps turned permanently on...........it would then give individual function on all four jets.

dave said he I now going to lie down in a dark room and stretch his brain power thinking about it.........

well that's my interpretation of the matter. |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Apr 30, 2019 9:30 pm Tue Apr 30, 2019 9:30 pm | |

| well, it's been a good 18 months since I did any work on this model...……...and sadly that was the last time I was to do any on it...……..

however, Martin Kinghoward [ aka Baloo] bought the boat off me at last years Blackpool show as I had sort of lost interest in the propulsion side of it.

But the good news is, martin is going to finish building it over the next few months, and I have suggested that as now he is a member on here, he would continue the build from here...….hopefully he will.

if any of you see him on the other forums including mayhem, could you urge and encourage him to put his posts on here as well.

thank you all.

neil |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Apr 30, 2019 11:09 pm Tue Apr 30, 2019 11:09 pm | |

| Lord help him if he doesnt put it up here M8

Dave |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Tue Apr 30, 2019 11:45 pm Tue Apr 30, 2019 11:45 pm | |

| |

|   | | Guest

Guest

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  Wed May 01, 2019 6:42 am Wed May 01, 2019 6:42 am | |

| |

|   | | Sponsored content

|  Subject: Re: STEAM HYDRAULIC LIFEBOAT Subject: Re: STEAM HYDRAULIC LIFEBOAT  | |

| |

|   | | | | STEAM HYDRAULIC LIFEBOAT |  |

|

Similar topics |  |

|

| | Permissions in this forum: | You cannot reply to topics in this forum

| |

| |

| |